Logic Design for Array-Based Circuits

by Donnamaie E. White

Copyright © 1996, 2001, 2002, 2008, 2016 Donnamaie E. White , WhitePubs Enterprises, Inc.

- Table of Contents

- Preface

- Overview

- Chapter 1 Introduction

- Chapter 2 Structured

Design Methodology

- Structured Design Methodology

- Review of the Available Arrays

- Initial Sizing of the Circuit

- Create the Preliminary Macro Schematic (when schematics are used)

- Compute the Path Propagation Delay

- Compute the Estimated Power

- Pre-Simultation Steps

- Simulation

- Fault Grading

- Design Submission Through Prototype

- Chapter 3 Sizing the Design

- Chapter 3 Appendix = Case Study in Sizing a Design

- Chapter 4 Design Optimization

- Chapter 5 Timing Analysis for Arrays

- Chapter 6 External Set-up and Hold Times

- Chapter 7 Power Considerations

- Case Study: DC Power Computation

- Case Study: AC Power Computation

- Chapter 8 Simulation

- Case Study: Simulationest

- Chapter 9 Faults and Fault Detectiond Output

- Chapter 10 Design Submission

- ASIC Glossary

Structured Design Methodology

Pre-Simulation Steps

Once an array or array series has been selected, the design can be captured and all checking performed with packaged or vendor software. For non-schematic designs, the steps leading to the netlist are performed per the system requirements. Once a netlist exists, the design steps are the same.

Perform Schematic Capture Through Netlist Generation

- Perform the schematic capture using the Dazix, Mentor, Valid or other

EWS (Electronic WorkStation) system; Lasar 6, Verilog or other netlister

equipped with schematic-generation software.

Perform the schematic capture following vendor schematic rules and conventions.

Perform the vendor-software steps through netlist generation

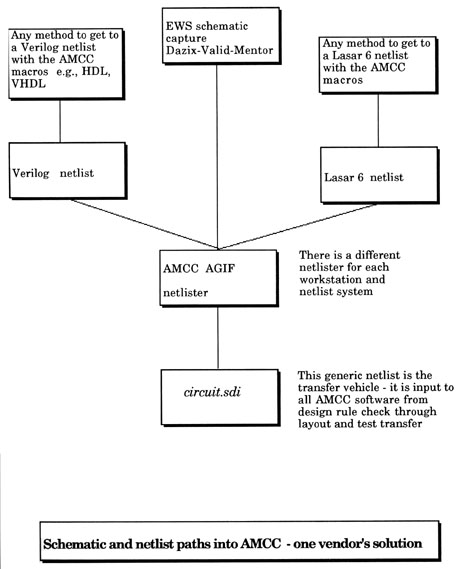

Each workstation has a different netlist format and a different procedure to generate it. Each workstation has its own simulator that uses the workstation-specific netlist as an input file. LASAR 6 (Vax/VMS) and Verilog each has a specific netlist format. Communication of a design from the design workstation to a vendor must be done using a netlist the array vendor can recognize. (See Figure 2-2.)

In the 90s, an array vendor was limited to accepting only those designs created on a workstation that matches the equipment that the vendor has in-house.

Most design input today is done without schematic capture. Cadence Composer can handle schematics. Design Compiler from Synopsys will display a schematic after synthesis (best used at the module level). Today;'s engineers use Verilog or VHDL netlist to input a circuit description. Design Compiler produces a Verilog netlist, an EDIF netlist and a Synopsys .db formatted file for design transfer.

Figure 2-2 Netlister Confusion

Another solution is the use of a dial-up design system based on a mainframe. The array vendor provides the account access for a fee and provides all required support and the designer provides an acceptable terminal. The problem is the access to a compatible terminal when a graphics terminal is required and the costs of the design in connect time.

To combat the problem of multiple formats without moving to a dial-up solution, netlist reformatters or translation programs have been written.

AMCC has a netlist formatter, AGIF, which is customized to each supported workstation and netlister. The AMCC Generic Interface Format file produced is called circuit.sdi and it is the means of communication between the customer and all AMCC software, including the MacroMatrix components: AMCCERC, AMCCANN, AMCCVRC, AMCCSIMFMT, AMCCSUBMIT and AMCCAD for placement.

Edif was just being born when this was in existence. Edif became the netlist of choice, except it must be translated to DEF for Cadence software use. There are a couple other formats - vendor-specific - that work off of edif or def or RTL. Engineers just love proprietary stuff. Until it comes time to interconnect with someone else's tools.

Perform Design Rules Checking

For systems and vendors without software support or with support that is less than complete, the design checks must be performed manually. EWS-based checking provided by the EWS vendor is minimal and should only be used as a first step in the validation process. Intelligent checkers are evolving. These may be interactive with a schematic capture or work on the standardized netlist.

The checker must be successfully completed before proceeding. Remove all errors if possible, and document those that remain. The vendor may require a waiver before submission if errors are not removed from the circuit.

AMCC customers must run AMCCERC and remove errors. The program output, AMCCERC.LST, provides reports on population, I/O types and mixes, utilization, package signal pin requirements, DC power, internal pin count, and SSO power-ground evaluation while listing naming violations, unconnected pins, pin connect violations, fan-out loading violations with derated loads, and technology (array, power-supply, and macro mismatch) errors. AMCCERC.LST must be included with the design submission package.

Design Compiler and other synthesis tools perform a certain amout of ERC checking. The final design rules checking (physical characteristics) are DRCs performed closer to wafer-fab. All timing, sizing and power checks should have passed review before reaching place & route. The circuit is also (usually) simulated early in the process to find errors. THe simulation runs off the RTL.

Generate Extrinsic Load Time Delays (Annotation)

The need for annotation software came from the change in the ratio between the delays caused by the interconnect between macros and the macro internal (intrinsic) delays. Once it was common for an interconnect net delay to exceed one half of the intrinsic delay, or even to exceed the intrinsic delay, it became necessary to produce a reasonable estimate of the interconnect delay.

Figure 2-3 Schematic And Netlist Paths Into AMCC

In 2000, the netlist standard had become edif. Verilog, VHD, edif, db, PDEF are transfer standards now.

Front-Annotation is the term used for pre-placement-pre-route interconnect delay estimation. The estimate is based on the net size, number of fan-out loads, both physical and electrical, or the capacitive load on an output macro.

The Front-Annotation programs such as AMCCANN compute the fan-out loading delay, the wire-OR loading delay, and provide an estimate of the metal etch delay due to the size of the nets. The estimate is based on a statistical evaluation of previously built circuits and the average etch length used to connect same-sized nets. It is too large a number some of the time and too small of a number at other times. Front-Annotation is not a specification.

Any loading anlysis performed prior to final place & route is not to ever be considered a final spec. For some reason, many designers cannot grasp this concept. It can lead to design failure.

Where Intermediate-Annotation is available (a Manhattan-Distance algorithm based on a placement file), it should be used. It is more accurate in more case but it is still an estimate. Only after place and route can the actual metal etch delays be known. Annotation after place & route is called Back-Annotation.

Perform Testability Analysis on the Circuit.

All testability measures have one common goal: to enhance controllability and observability of the circuit. It is a grade on the logic design itself. Controllability is a measure of the ease in setting a particular node to a logic level of zero or one, while observability determines the ease of propagating the node's state to one or more primary outputs.

After a netlist has been created and logic simulation has verified correct functional performance, testability can be verified by running testability analysis programs. This optional step is highly recommended if there is software available to perform the analysis. For a modular design, a manual review should be performed if there is no software support.

The purpose is to identify those parts of the circuit that are difficult or impossible to reach by way of primary inputs (controllability), and those parts of the circuit that may change state but that are difficult or impossible to observe at a primary output (observability). Steps should be taken to make hard to reach nodes controllable by adding test control signals and degating logic. Make hard to observe nodes observable by adding test points.

Make any adjustments or changes to the schematic as necessary to improve testability to acceptable limits. Changing the schematic will mean repeating the error-checking and annotation software steps.

Testability analysis should be done before simulation since the result will be to simplify the functional simulation vector set development.

Copyright © 1996, 2001, 2002, 2008, 2016 Donnamaie E. White , WhitePubs

Enterprises, Inc.

For problems or questions on these pages, contact [email protected]